This tutorial is the first part of our STM32 ADC Tutorial Series. In this tutorial series, you’ll learn everything about ADC in STM32 microcontrollers. We’ll go through examples for each and every single mode of operation (Single-Channel, Multi-Channel, Scan, Continuous Conversion, Discontinuous Mode, Injected Channels, Analog Watchdog, etc). We’ll perform the ADC data reading with all possible techniques for every mode of operation (using Polling, Interrupt, and DMA).

This pretty long journey starts off here, in this STM32 ADC Tutorial, where we’ll introduce all the fundamentals and the knowledge base that we’ll be using in later tutorials in this series. Without further ado, let’s get right into it!

Table of Contents

- Introducing STM32 ADC

- ADC in STM32 Microcontrollers

- STM32 ADC Functional Description

- STM32 ADC Modes of Operation

- STM32 ADC External & Internal Triggers

- STM32 ADC Calibration

- STM32 ADC Sampling Time

- STM32 ADC Resolution, Reference, Formulas

- STM32 ADC Interrupts

- STM32 ADC With DMA

- Reading ADC in STM32 (Poll, Interrupt, DMA)

- STM32 ADC Error Sources

- STM32 ADC Example Applications

Introducing STM32 ADC

An ADC (Analog-To-Digital) converter is an electronic circuit that takes in an analog voltage as input and converts it into digital data, a value that represents the voltage level in binary code. The ADC samples the analog input whenever you trigger it to start conversion. It performs a process called quantization to decide on the voltage level and its binary code that gets pushed into the output register.

The ADC does the counter operation that of a DAC, while an ADC (A/D) converts analog voltage to digital data the DAC (D/A) converts digital numbers to the analog voltage on the output pin.

The ADC is one of the most expensive electronic components especially when it does have a high sampling rate and high resolution. Therefore, it’s a valuable resource in microcontrollers and different manufacturers provide us (the firmware engineers) with various features to make the best use of it. And the flexibility also to make a lot of decisions like sacrificing resolution in exchange for a higher resolution or having the ADC to trigger on an internal timer signal to periodically sample the analog channels, and much more as we’ll see in this tutorial.

For those who like to have a solid introduction to ADC, how it works at the low level, different types of ADCs, ADC errors, equations, and all other details. The ADC Tutorial down below is a complete introductory guide for this topic and is highly recommended.

This article will give more in-depth information about analog-to-digital converters, how they work, what are the fundamental parameters & equations that define the operation of an ADC, and much more.

ADC in STM32 Microcontrollers

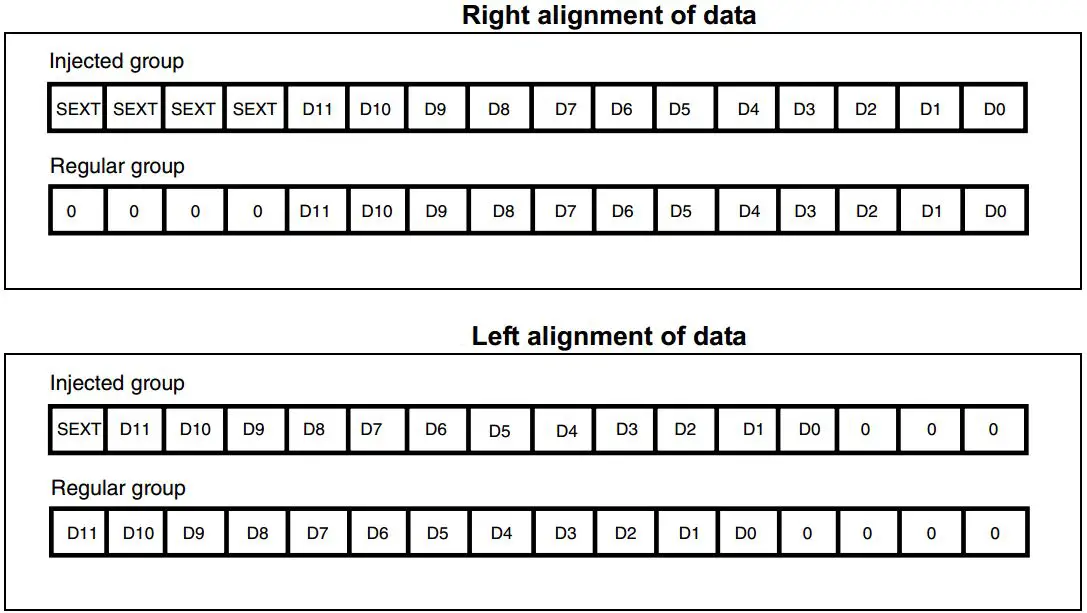

The STM32F103C8 (Blue Pill) & STM32F432KC both have a 12-bit ADC which is a successive approximation analog-to-digital converter. It has up to 18 multiplexed channels allowing it to measure signals from sixteen external and two internal sources. A/D conversion of the various channels can be performed in single, continuous, scan, or discontinuous mode. The result of the ADC is stored in a left-aligned or right-aligned 16-bit data register.

ADC Features

- 12-bit resolution

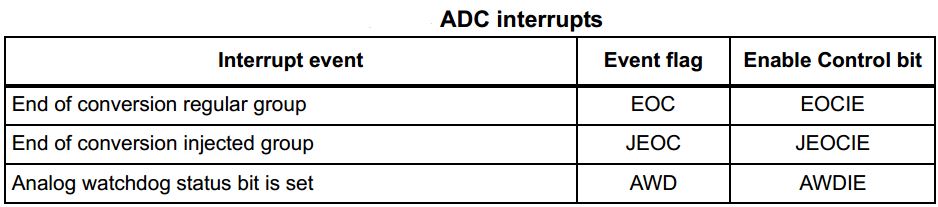

- Interrupt generation at the End of Conversion, End of Injected conversion, and Analog watchdog event

- Single and continuous conversion modes

- Scan mode for automatic conversion of channel 0 to channel ‘n’

- Self-calibration

- Data alignment with in-built data coherency

- Channel-by-channel programmable sampling time

- External trigger option for both regular and injected conversion

- Discontinuous mode

- Dual-mode (on devices with 2 ADCs or more)

- ADC conversion time: 1 µs at 56 MHz (1.17 µs at 72 MHz)

- ADC supply requirement: 2.4 V to 3.6 V

- ADC input range: VREF– ≤ VIN ≤ VREF+

- DMA request generation during regular channel conversion

STM32 ADC Functional Description

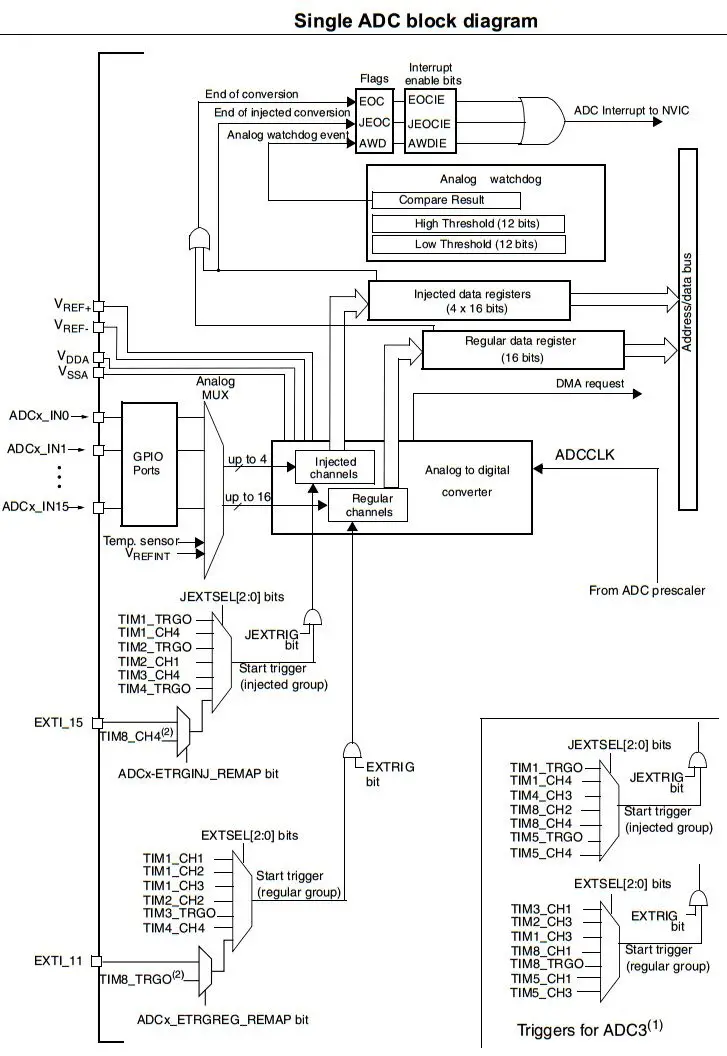

STM32 ADC Block Diagram

STM32 ADC Clock

The ADCCLK clock provided by the Clock Controller is synchronous with the PCLK2 (APB2 clock). The RCC controller has a dedicated programmable Prescaler for the ADC clock, and it must not exceed 14 MHz.

STM32 ADC Channel Selection

There are 16 multiplexed channels. It is possible to organize the conversions into two groups: regular and injected. A group consists of a sequence of conversions that can be done on any channel and in any order. For instance, it is possible to do the conversion in the following order: Ch3, Ch8, Ch2, Ch2, Ch0, Ch2, Ch2, Ch15.

The Regular Group is composed of up to 16 conversions.

The Injected Group is composed of up to 4 conversions.

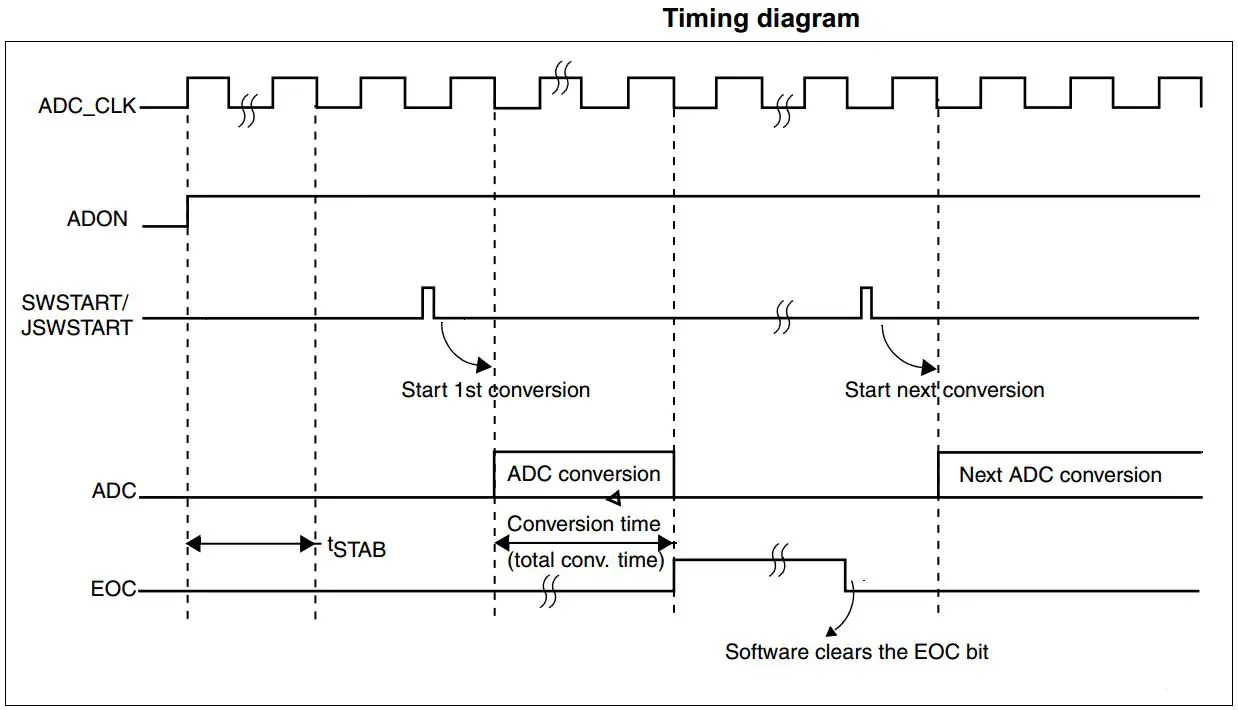

ADC Conversion Time & Timing Diagram

the ADC needs a stabilization time of tSTAB before it starts converting accurately. After the start of ADC conversion and after 14 clock cycles, the EOC flag is set and the 16-bit ADC Data register contains the result of the conversion.

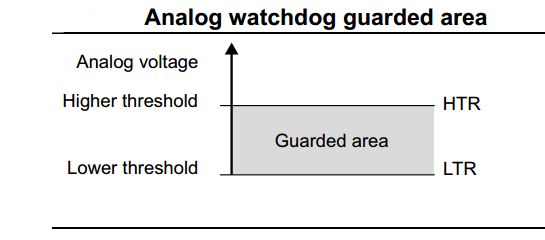

The ADC Analog Watchdog (AWD)

The STM32 Analog Watchdog ADC Mode acts like a window comparator running in the background of the ADC operation. Its job is to check the voltage level of the AWD-enabled channels to make sure it’s within the “programmed” threshold levels. If the analog input voltage goes out of the configured voltage window, the AWD will fire an interrupt.

ADC Result Data Alignment

The ADC result data is 12 bits in width and the buffer register is 16 bits. Therefore, it can be left or right-aligned as shown in the diagram below. The injected group channels converted data value can be decreased by the user-defined offset written in the ADC_JOFRx registers so the result can be a negative value. The SEXT bit is the extended sign value. For regular group channels, no offset is subtracted so only twelve bits are significant.

STM32 ADC Modes of Operation

There are so many operating modes for the STM32 ADC to give us, the system designers/programmers, the flexibility to configure it in any way imaginable that suits the application’s needs. This comes at the cost of having a really complex piece of hardware that can be configured in so many ways as we’ll briefly discuss here in this section. Each mode has a dedicated tutorial in this STM32 ADC tutorial series.

Single Conversion Mode

In Single Conversion mode, the ADC does one conversion. This mode is started either by setting the ADON bit in the ADC_CR2 register (for a regular channel only) or by an external trigger (for a regular or injected channel), while the CONT bit is 0. Once the conversion of the selected channel is complete:

- If a regular channel was converted:

– The converted data is stored in the 16-bit ADC_DR register

– The EOC (End Of Conversion) flag is set

– and an interrupt is generated if the EOCIE is set. - If an injected channel was converted:

– The converted data is stored in the 16-bit ADC_DRJ1 register

– The JEOC (End Of Conversion Injected) flag is set

– and an interrupt is generated if the JEOCIE bit is set.

The ADC is then stopped.

Continuous Conversion Mode

In continuous conversion mode, ADC starts another conversion as soon as it finishes one. This mode is started either by an external trigger or by setting the ADON bit in the ADC_CR2 register, while the CONT bit is 1. After each conversion:

- If a regular channel was converted:

– The converted data is stored in the 16-bit ADC_DR register

– The EOC (End Of Conversion) flag is set

– An interrupt is generated if the EOCIE is set. - If an injected channel was converted:

– The converted data is stored in the 16-bit ADC_DRJ1 register

– The JEOC (End Of Conversion Injected) flag is set

– An interrupt is generated if the JEOCIE bit is set.

Scan Mode

This mode is used to scan a group of analog channels. A single conversion is performed for each channel of the group. After each end of conversion, the next channel of the group is converted automatically. If the CONT bit is set, conversion does not stop at the last selected group channel but continues again from the first selected group channel.

When using scan mode, DMA bit must be set and the direct memory access controller is used to transfer the converted data of regular group channels to SRAM after each update of the ADC_DR register. The injected channel converted data is always stored in the ADC_JDRx registers.

Discontinuous Mode

This mode is enabled by setting the DISCEN bit in the ADC_CR1 register. It can be used to convert a short sequence of n conversions (n <=8) which is a part of the sequence of conversions selected in the ADC_SQRx registers. The value of n is specified by writing to the DISCNUM[2:0] bits in the ADC_CR1 register.

When an external trigger occurs, it starts the next n conversions selected in the ADC_SQRx registers until all the conversions in the sequence are done. The total sequence length is defined by the L[3:0] bits in the ADC_SQR1 register.

STM32 ADC External & Internal Triggers

The default option to trigger the STM32 ADC to start the conversion process is the Software Trigger source. Therefore, we had to manually call the HAL_ADC_Start() function whenever we wanted to start a new ADC conversion. However, the ADC can also be automatically triggered by internal or external trigger sources in the STM32 microcontroller itself.

This can be really useful to set the ADC conversion to occur periodically using a timer trigger to achieve a desired ADC sampling rate. Or to trigger the ADC conversion to start at a specific time relative to some output PWM signal (a very important feature for advanced measurement systems).

This mode is explained in more detail with practical example projects in a dedicated tutorial in this STM32 ADC series.

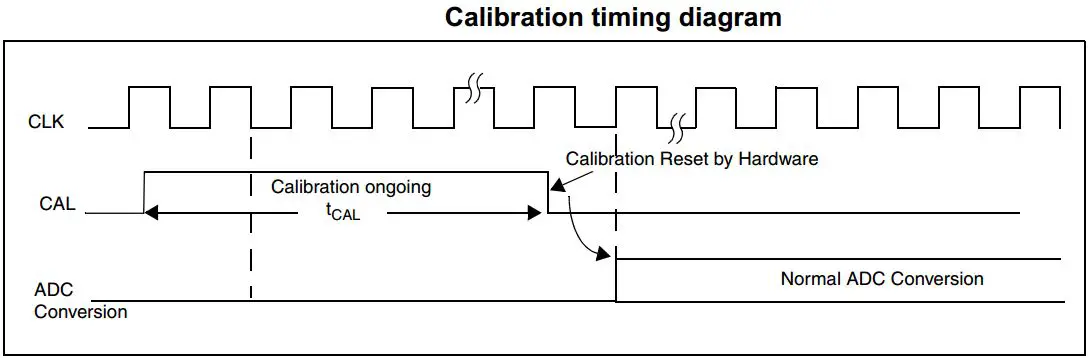

STM32 ADC Calibration

The ADC has a built-in self-calibration mode. Calibration significantly reduces accuracy errors due to internal capacitor bank variations. During calibration, an error correction code (digital word) is calculated for each capacitor, and during all subsequent conversions, the error contribution of each capacitor is removed using this code.

Calibration is started by setting the CAL bit in the ADC_CR2 register. Once calibration is over, the CAL bit is reset by hardware and normal conversion can be performed. It is recommended to calibrate the ADC once at power on. The calibration codes are stored in the ADC_DR as soon as the calibration phase ends. It is recommended to perform a calibration after each power-up.

The STM32 HAL does provide a function within the ADC APIs dedicated to starting the calibration process and as said before it’s a recommended step after initializing the ADC hardware at the system power-up.

STM32 ADC Sampling Time

The STM32 ADC samples the input voltage for a number of ADC_CLK cycles which can be modified using the SMP[2:0] bits in the ADC_SMPR1 and ADC_SMPR2 registers. Each channel can be sampled with different sample times.

The Total ADC Conversion Time is calculated as follows:

Tconv = Sampling time + 12.5 cycles

Example:

With an ADCCLK = 14 MHz and a sampling time of 1.5 cycles: Tconv = 1.5 + 12.5 = 14 cycles = 1 µs

The ADC Sampling Rate (Frequency) is calculated using this formula:

SamplingRate = 1 / Tconv

For The Previous example where Tconv = 1µs, The samplingRate = 1000000 = 1Ms/sec

STM32 ADC Resolution, Reference, Formulas

STM32 ADC Resolution

The STM32 ADC has a resolution of 12-bit which results in a total conversion time of SamplingTime+12.5 clock cycles. However, higher sampling rates can be achieved by sacrificing the high resolution. Therefore, the resolution can be dropped down to 10-bit, 8-bit, or 6-bit, and hence the conversion time is much shorter, and the sampling rate increases.

This can be configured and implemented in software by the programmer and the STM32 HAL does provide APIs to set all the ADC parameters including its resolution.

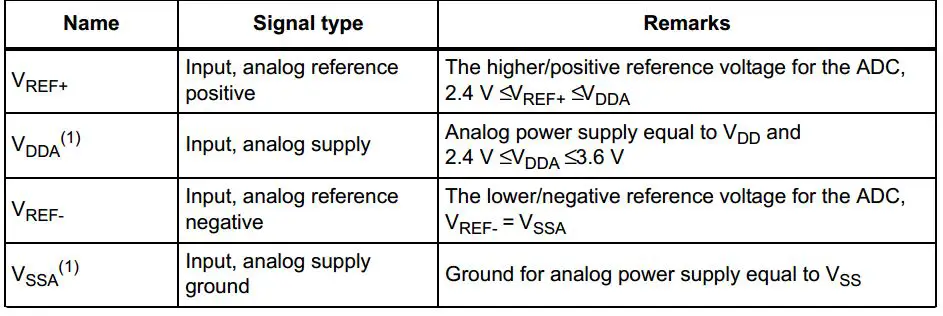

ADC Reference Voltage

The ADC reference voltage pins are defined in the datasheet and assumed to be connected to a voltage level in a certain range. This is shown in the table below. You can choose to set the reference voltage to its maximum allowable level for a wider range of conversion but less voltage measurement resolution. Alternatively, you can set the reference voltage to the minimum allowable value for better voltage reading resolution.

If you’re using a development board, you may need to check out its schematic diagram as it may not be connecting the ADC Vref at all or connecting it to a 2.5v for example, so the ADC will saturate and give you 4096 before the input analog voltage reaches 3.3v and you’re wondering why! it may be because the reference voltage is set to a value less than 3.3v, so it’s something to consider.

STM32 ADC Formulas

ADC Conversion Time

Tconv = Sampling time + 12.5 cycles

ADC Sampling Rate

SamplingRate = 1 / Tconv

ADC Result Voltage (Analog Input Value)

Vin = ADC_Res x (Reference Voltage / 4096)

Where, Reference Voltage = (VREF+) – (VREF-)

STM32 ADC Interrupts

An interrupt can be produced at the end of conversion for regular and injected groups and when the analog watchdog status bit is set. Separate interrupt enable bits are available for flexibility.

STM32 ADC With DMA

Since converted regular channel values are stored in a unique data register, it is necessary to use DMA for the conversion of more than one regular channel. This avoids the loss of data already stored in the ADC_DR register.

Only the end of the conversion of a regular channel generates a DMA request, which allows the transfer of its converted data from the ADC_DR register to the destination location selected by the user.

Reading ADC in STM32 (Poll, Interrupt, DMA)

There are mainly three different ways to read the STM32 ADC conversion result upon conversion completion. In this section, we’ll briefly describe each method and in the following tutorials, we’ll implement all of those 3 techniques for each operation mode of the ADC.

1) STM32 ADC Polling

It’s the easiest way in code to perform an analog-to-digital conversion using the ADC on an analog input channel. However, it’s not an efficient way in all cases as it’s considered to be a blocking way of using the ADC. Because in this way we start the A/D conversion and wait for the ADC until it completes the conversion so the CPU can resume processing the main code.

2) STM32 ADC Interrupt

The interrupt method is an efficient way to do ADC conversion in a non-blocking manner, so the CPU can resume executing the main code routine until the ADC completes the conversion and fires an interrupt signal so the CPU can switch to the ISR context and save the conversion results for further processing.

However, when you’re dealing with multiple channels in a circular mode or so, you’ll have periodic interrupts from the ADC that are too much for the CPU to handle. This will introduce jitter injection, interrupt latency, and all sorts of timing issues to the system. This can be avoided by using DMA.

3) STM32 ADC DMA

Lastly, the DMA method is the most efficient way of converting multiple ADC channels at very high rates and still transfers the results to the memory without CPU intervention which is so cool and time-saving technique.

Note That: Code Examples For The 3 Methods Are Provided in The Next Tutorials.

The next section will help you identify and optimize the error sources in your STM32 ADC measurement system. However, it’s not mandatory for everyone to study it in the meantime and you can now move on to the next part of this STM32 ADC tutorial series.

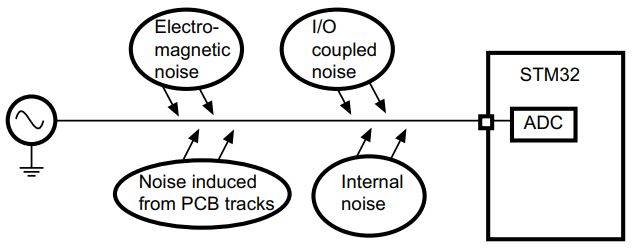

STM32 ADC Error Sources

This section lists the main error types that have an effect on A/D conversion accuracy. These types of errors occur in all A/D converters and conversion quality depends on eliminating the source of each error of them.

1) ADC Errors Due To The ADC Itself

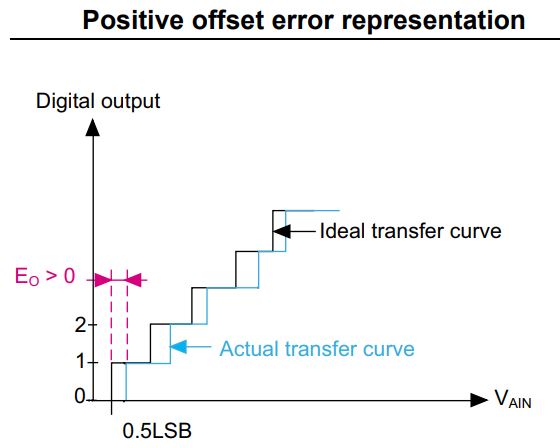

1.1 – ADC Offset Error

The offset error is the deviation between the first actual transition and the first ideal transition. The first transition occurs when the digital ADC output changes from 0 to 1. Ideally, when the analog input ranges between 0.5 LSB and 1.5 LSB, the digital output should be 1. Still, ideally, the first transition occurs at 0.5 LSB. The offset error is denoted by EO. The offset error can easily be calibrated by the application firmware.

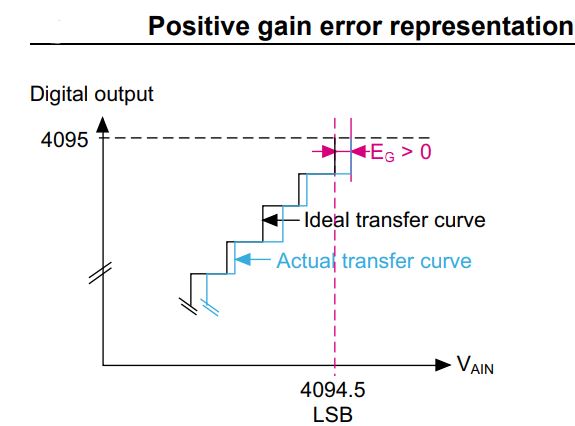

1.2- ADC Gain Error

The gain error is the deviation between the last actual transition and the last ideal transition. It is denoted by EG. The last actual transition is the transition from 0xFFE to 0xFFF. Ideally, there should be a transition from 0xFFE to 0xFFF when the analog input is equal to VREF+ – 0.5 LSB. So for VREF+= 3.3 V, the last ideal transition should occur at 3.299597 V. If the ADC provides the 0xFFF reading for VAIN < VREF+ – 0.5 LSB, then a negative gain error is obtained. The gain error is obtained by the formula below:

EG = Last actual transition – ideal transition

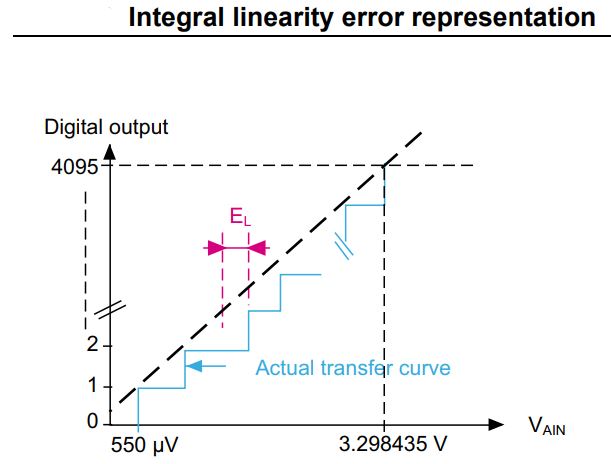

1.3 – Integral Linearity Error

The integral linearity error is the maximum deviation between any actual transition and the endpoint correlation line. The ILE is denoted by EL. The endpoint correlation line can be defined as the line on the A/D transfer curve that connects the first actual transition with the last actual transition.

EL is the deviation from this line for each transition. The endpoint correlation line thus corresponds to the actual transfer curve and has no relation to the ideal transfer curve. The ILE is also known as the integral non-linearity error (INL). The ILE is the integral of the DLE over the whole range.

2) ADC Errors Due To The Environment

2.1 – ADC Reference Voltage Noise

As the ADC output is the ratio between the analog signal voltage and the reference voltage, any noise on the analog reference causes a change in the converted digital value. VDDA analog power supply is used on some packages as the reference voltage (VREF+), so the quality of the VDDA power supply has an influence on ADC error.

2.2 – Analog Input Signal Noise

Small but high-frequency signal variation can result in big conversion errors during sampling time. This noise is generated by electrical devices, such as motors, engine ignition, power lines. It affects the source signal (such as sensors) by adding an unwanted signal. As a consequence, the ADC conversion results are not accurate.

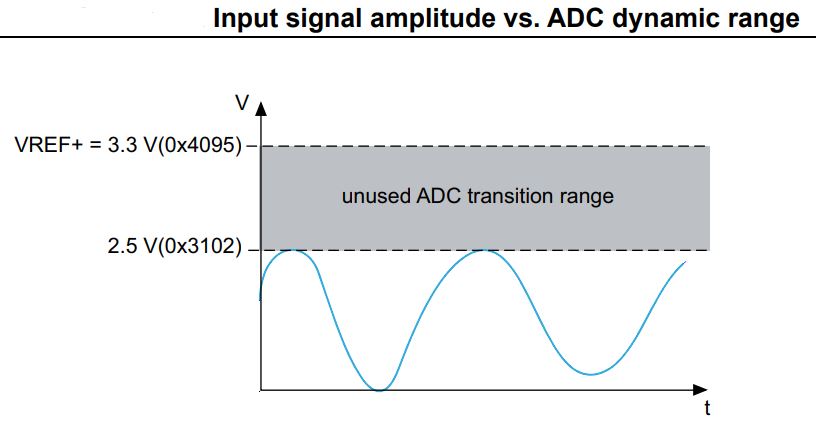

2.3 – ADC Dynamic Range Bad Matching

To obtain the maximum ADC conversion precision, it is very important that the ADC dynamic range matches the maximum amplitude of the signal to be converted. Let us assume that the signal to be converted varies between 0 V and 2.5 V and that VREF+ is equal to 3.3 V. The maximum signal value converted by the ADC is 3102 (2.5 V) as shown in the diagram down below. In this case, there are 993 unused transitions (4095 – 3102 = 993). This implies a loss in the converted signal accuracy.

2.4 – Analog Signal Source Impedance (Resistance)

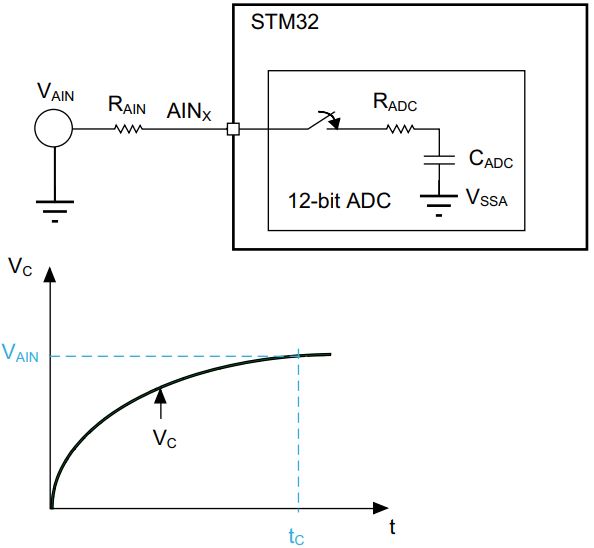

The impedance of the analog signal source, or series resistance (RAIN), between the source and pin, causes a voltage drop across it because of the current flowing into the pin. The charging of the internal sampling capacitor (CADC) is controlled by switches with a resistance RADC. With the addition of source resistance (with RADC), the time required to fully charge the hold capacitor increases.

If the sampling time is less than the time required to fully charge the CADC through RADC + RAIN (ts < tc), the digital value converted by the ADC is less than the actual value.

This error can be reduced or completely eliminated by setting the sampling time of the analog channel in such a way that guarantees an appropriate voltage level on the input pin is present before the ADC starts the conversion.

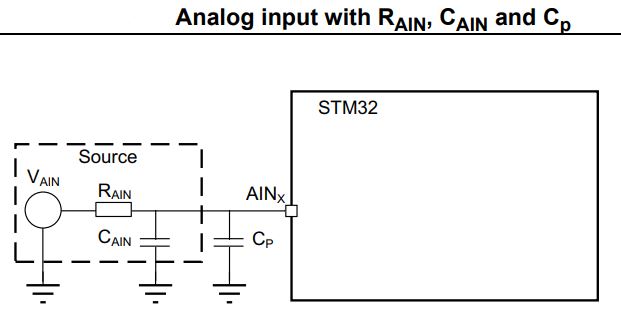

2.5 – Analog Signal Source Capacitance & Parasitics

When converting analog signals, it is necessary to account for the capacitance at the source and the parasitic capacitance seen on the analog input pin. The source resistance and capacitance form an RC network. In addition, the ADC conversion results may not be accurate unless the external capacitor (CAIN + Cp) is fully charged to the level of the input voltage.

The greater value of (CAIN + Cp), the more limited the source frequency. The external capacitance at the source and the parasitic capacitance are denoted by CAIN and Cp, respectively.

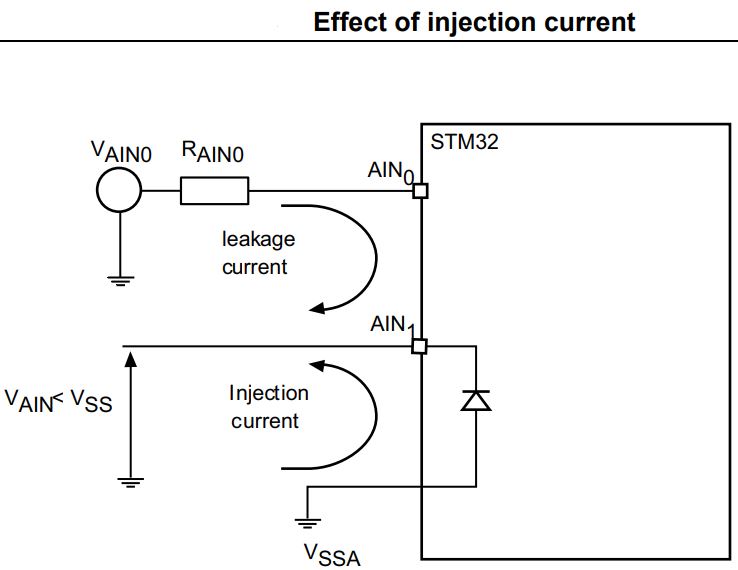

2.6 – Injection Current Effect

A negative injection current on any analog pin (or a closely positioned digital input pin) may introduce leakage current into the ADC input. The worst case is the adjacent analog channel. A negative injection current is introduced when VAIN < VSS, causing current to flow out from the I/O pin. Which can potentially shift the voltage level on the pin and distort the measurement result.

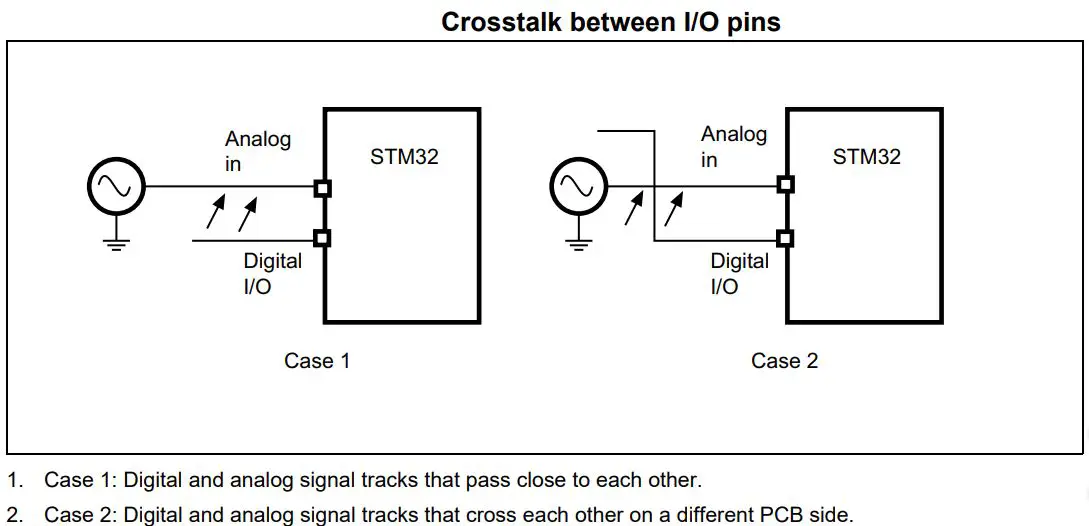

2.7 – IO Pins Cross-Talking

Switching the I/Os may induce some noise in the analog input of the ADC due to capacitive coupling between I/Os. Crosstalk may be introduced by PCB tracks that run close to each other or that cross each other.

Internally switching digital signals and IOs introduces high-frequency noise. Switching high sink I/Os may induce some voltage dips in the power supply caused by current surges. A digital track that crosses an analog input track on the PCB may affect the analog signal.

2.8 – EMI-Induced Noise

Electromagnetic emissions from neighboring circuits may introduce high-frequency noise in an analog signal because the PCB tracks may act as an antenna. It’s called electromagnetic interference (EMI) noise.

STM32 ADC Example Applications

In the next few tutorials, we’ll be practicing the ADC peripheral and doing some practical LABs to learn how to configure and program the ADC to do certain tasks in different ways. The ADC example applications will include the following:

Good tutorial.

This is simply the best tutorial I have seen explaining the behind-the-scenes of ADC. Truly, thank you.

Amazing work. Thanks a lot!

Thank you. please, could you show how to use STM32F103C8 ADC in dual regular mode?

How to read the hex values from controller using adc in stm32f401 board.

The easiest way is to use the “STM32 ADC Single-Channel Single-Conversion (With Polling) Example” that you can find in the tutorial below:

https://deepbluembedded.com/stm32-adc-read-example-dma-interrupt-polling/

Use the sprintf() function with USB CDC as shown in the following tutorial’s example:

https://deepbluembedded.com/stm32-usb-cdc-virtual-com-port-vcp-examples/

Instead of printing the variable with (%d) decimal identifier, you can use: sprintf(“0x%04X”, AD_RES);

This should print out the HEX result of the ADC reading